For size, our company is equipped with arc size sorting machine of Keyence, which reduces the risk caused by bad batch of tolerance control assembly part magnet assembly of customers.

No matter what kind of coating, we all can ensure the arc special treatment on the surface of the segment for the colloid affinity of magnet to the solutions in the use process where the stick, the embedded glue tension is insufficient and so on.

For delivery terms, we have a variety of blanks in different sizes and grades, for making prototype magnet at any time. We order powder in bulk in advance so that flexible dual alloy technology can satisfy the customer delivery requirements after receiving customer demand.

Our company is equipped with professional technical and sales team which can provide technical advice, magnet assembly scheme, and a large number of use cases at any time to ensure that have no additional worries in the process of using for clients.

We strictly abide by the standards of process controlling, the flow controlling in accordance with the IATF16949 system, to ensure delivery and quality monitoring for customers.

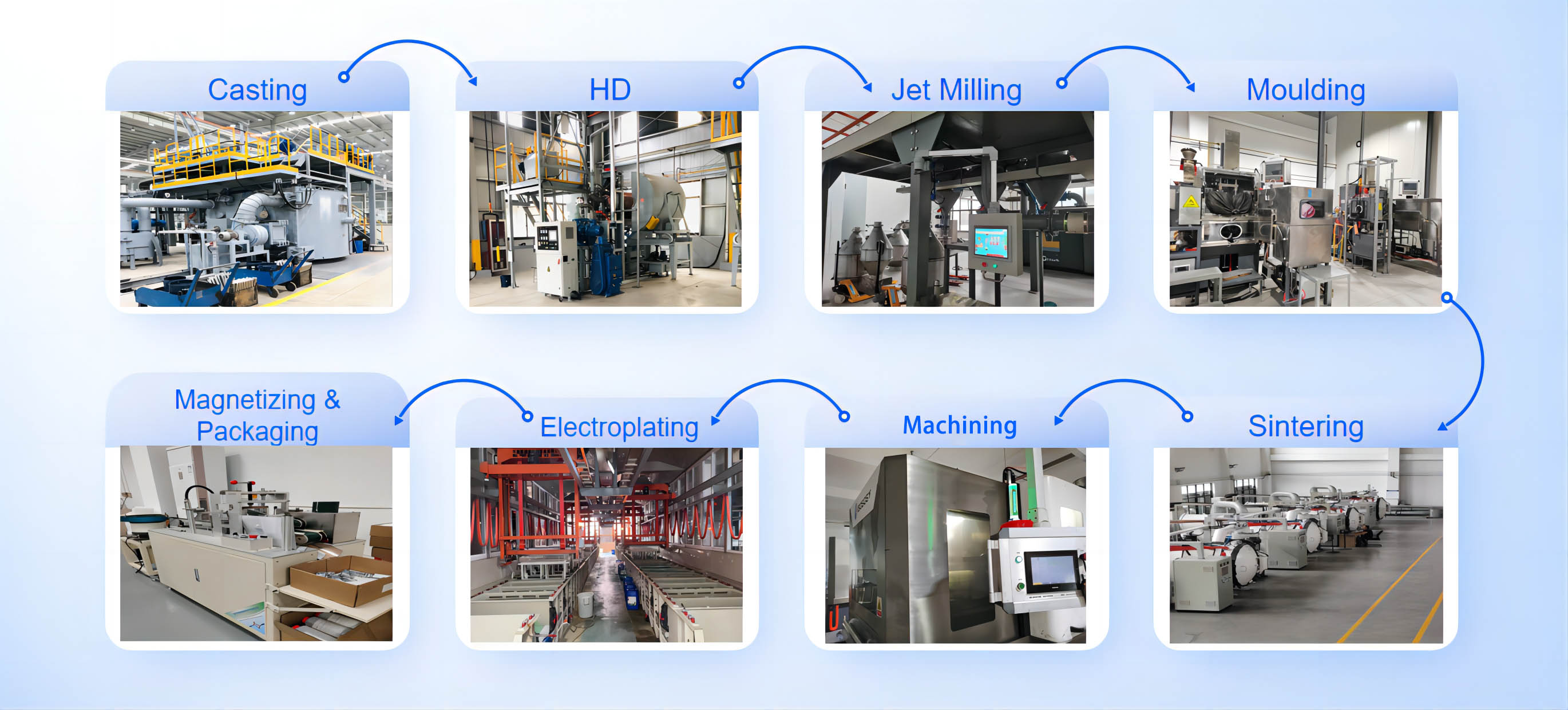

NdFeB Production Process

Coating Introduction

| Surface | Coating | Thickness μm | Color | SST Hours | PCT Hours | |

| Nickel | Ni | 10~20 | Bright Silver | >24~72 | >24~72 | |

| Ni+Cu+Ni | ||||||

| Black Nickel | Ni+Cu+Ni | 10~20 | Bright Black | >48~96 | >48 | |

| Cr3+Zinc | Zn C-Zn |

5~8 | Brighe Blue Shining Color |

>16~48 >36~72 |

--- | |

| Sn | Ni+Cu+Ni+Sn | 10~25 | Silver | >36~72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10~15 | Gold | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10~ 15 | Silver | >12 | >48 | |

| Epoxy |

Epoxy | 10~20 | Black/Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15~30 | >72~108 | --- | |||

| Zn+Epoxy | 15~25 | >72~108 | --- | |||

| Passivation | --- | 1~3 | Dark Grey | Temporary Protection | --- | |

| Phosphate | --- | 1~3 | Dark Grey | Temporary Protection) | --- | |

Physical Characteristics

| Item | Parameters | Reference Value | Unit |

| Auxiliary Magnetic Properties |

Reversible Temperature Coefficient Of Br | -0.08--0.12 | %/℃ |

| Reversible Temperature Coefficient Of Hcj | -0.42~-0.70 | %/℃ | |

| Specific Heat | 0.502 | KJ·(Kg ·℃)-1 | |

| Curie Temperature | 310~380 | ℃ | |

| Mechanical Physical Properties |

Density | 7.5~7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Electrical Resistance | 1.4x10-6 | μQ ·m | |

| Compressive Strength | 1050 | MPa | |

| Tensile Strength | 80 | Mpa | |

| Bending Strength | 290 | Mpa | |

| Thermal Conductivity | 6~8.95 | W/m ·K | |

| Young's Modulus | 160 | GPa | |

| Thermal Expansion(C⊥) | -1.5 | 10-6/℃-1 | |

| Thermal Expansion(CII) | 6.5 | 10-6/℃-1 |

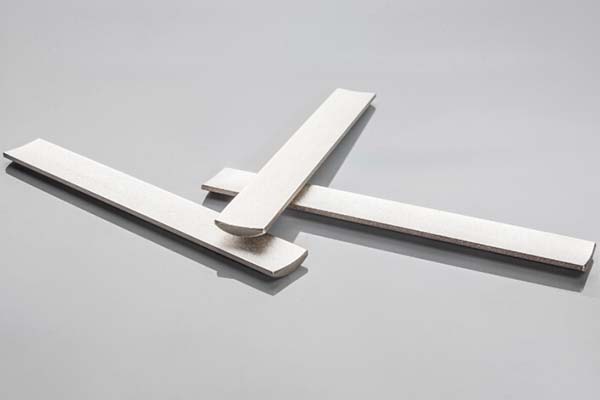

Picture Display