Application: NdFeB ring are widely used in hollow cup motor, vacuum cleaner motor, hair dryer motor, loudspeaker and other fields. In motor applications,it has very high requirement on magnet geometric dimension and magnet property, the minimum tolerance can be within 0-0.03mm.In loudspeaker application, the magnet are normally with Zn coating, delivery under un-magnetized condition, magnet grade like N, M and H series grade, normally loudspeaker magnet don't need higher grade.Another application is for cosmetic market,we are providing millions pieces ring magnet to our clients all over the world, the magnets are used for packaging box,axial magnetized or multipole axial magnetized like 2 or 4 poles, and not only for pure magnet, we are also avaialbe for some magnet assembly.

Products customized: Our ring magnet can be customized from 3mm-200mm outer diameter, 1mm-150mm inner diameter, thickness from 1mm-70mm.It also need coating most of the time, like NiCuNi, Zn, Epoxy and so on...

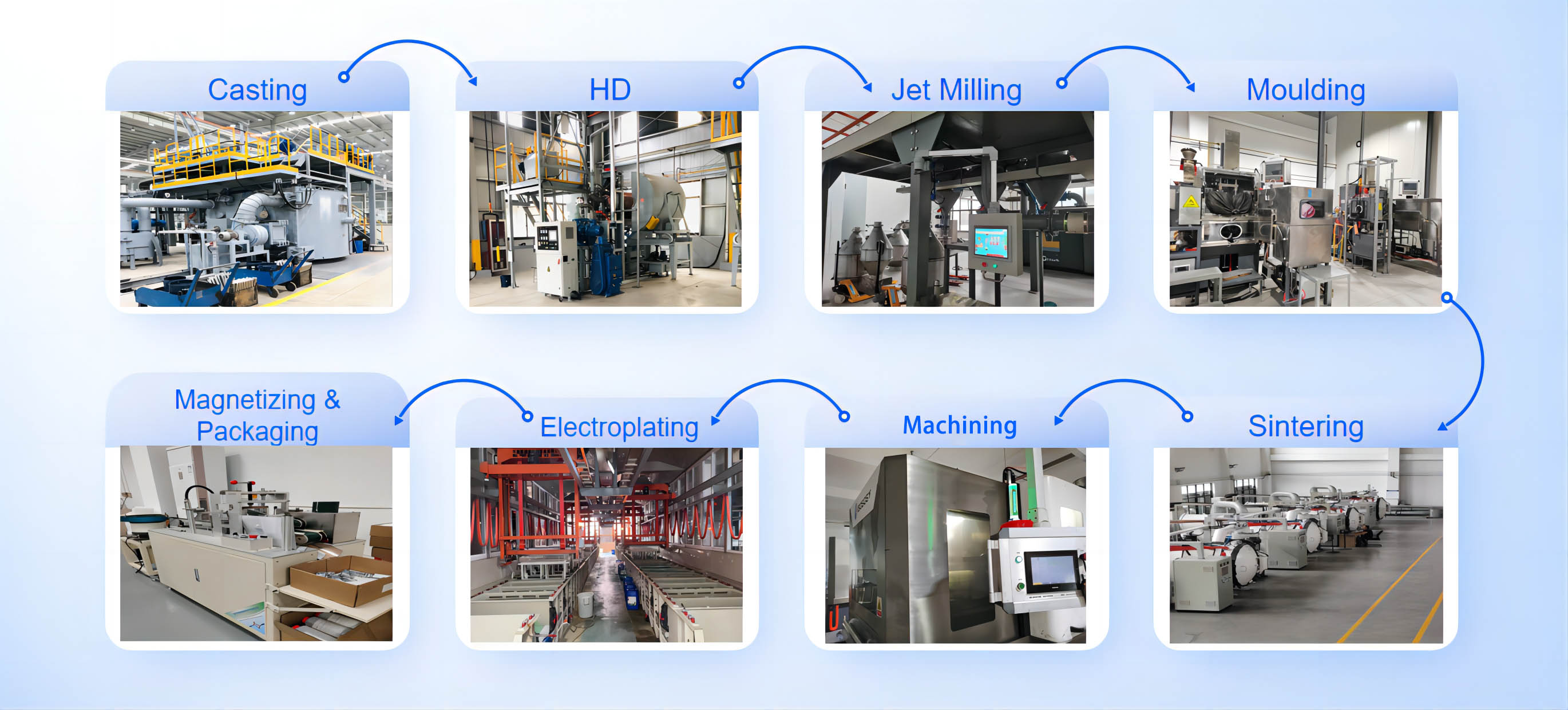

NdFeB Production Process

Coating Introduction

| Surface | Coating | Thickness μm | Color | SST Hours | PCT Hours | |

| Nickel | Ni | 10~20 | Bright Silver | >24~72 | >24~72 | |

| Ni+Cu+Ni | ||||||

| Black Nickel | Ni+Cu+Ni | 10~20 | Bright Black | >48~96 | >48 | |

| Cr3+Zinc | Zn C-Zn |

5~8 | Brighe Blue Shining Color |

>16~48 >36~72 |

--- | |

| Sn | Ni+Cu+Ni+Sn | 10~25 | Silver | >36~72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10~15 | Gold | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10~ 15 | Silver | >12 | >48 | |

| Epoxy |

Epoxy | 10~20 | Black/Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15~30 | >72~108 | --- | |||

| Zn+Epoxy | 15~25 | >72~108 | --- | |||

| Passivation | --- | 1~3 | Dark Grey | Temporary Protection | --- | |

| Phosphate | --- | 1~3 | Dark Grey | Temporary Protection) | --- | |

Physical Characteristics

| Item | Parameters | Reference Value | Unit |

| Auxiliary Magnetic Properties |

Reversible Temperature Coefficient Of Br | -0.08--0.12 | %/℃ |

| Reversible Temperature Coefficient Of Hcj | -0.42~-0.70 | %/℃ | |

| Specific Heat | 0.502 | KJ·(Kg ·℃)-1 | |

| Curie Temperature | 310~380 | ℃ | |

| Mechanical Physical Properties |

Density | 7.5~7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Electrical Resistance | 1.4x10-6 | μQ ·m | |

| Compressive Strength | 1050 | MPa | |

| Tensile Strength | 80 | Mpa | |

| Bending Strength | 290 | Mpa | |

| Thermal Conductivity | 6~8.95 | W/m ·K | |

| Young's Modulus | 160 | GPa | |

| Thermal Expansion(C⊥) | -1.5 | 10-6/℃-1 | |

| Thermal Expansion(CII) | 6.5 | 10-6/℃-1 |

Picture Display