It is suitable for many fields and industries, including electronics, medical, automotive, machinery, etc. Whether in sensors, motors, sound equipment or other applications, our products always show outstanding performance and consistent quality. Our other shapes NdFeb products have already achieved great success in numerous projects and applications.

For example, in the drive system of electric vehicle, our products contribute to efficient motor property and power output. We also provide critical magnetic support for a wide range of medical devices in the medical equipment field. So customers have highly praised the quality and performance of our products.

In the competitive market, our products have a stronger advantage. Because we have advanced producing processes and equipment to ensure the stability and consistency of product quality. We also continuously develop and innovate to meet the changing needs of our customers. Our process strictly controls every link to ensure that products meet high quality requirements.

We offer a variety of solutions to meet the specific needs of our customers. Our professional team works closely with our customers to understand their applications and needs in order to provide solutions for them on the best product selection and design.

We are committed to providing our customers with tailor-made solutions to ensure that they can fully leverage the benefits of other shapes Ndfeb products to achieve greater efficiency and performance.

We also provide excellent after-sales service to our customers. Whether it is the installation, commissioning or maintenance of the product, we will provide timely support and guidance.

We adhere to the principle of customer first, always put customer satisfaction in the first place, and strive to provide customers with the best after-sales experience.

As a manufacturer of Ndfeb, our other shapes NdFeb products stand out for their strong magnetic properties, unique shape design and wide range of applications.

Our technical support, customer review, after-sales service and competitive advantage further strengthen our position in the market. We will continue to be committed to technological innovation and product optimization, to provide customers with more high-quality and diversified shapes NdFeb products to make greater contributions to the development and innovation of all walks of life.

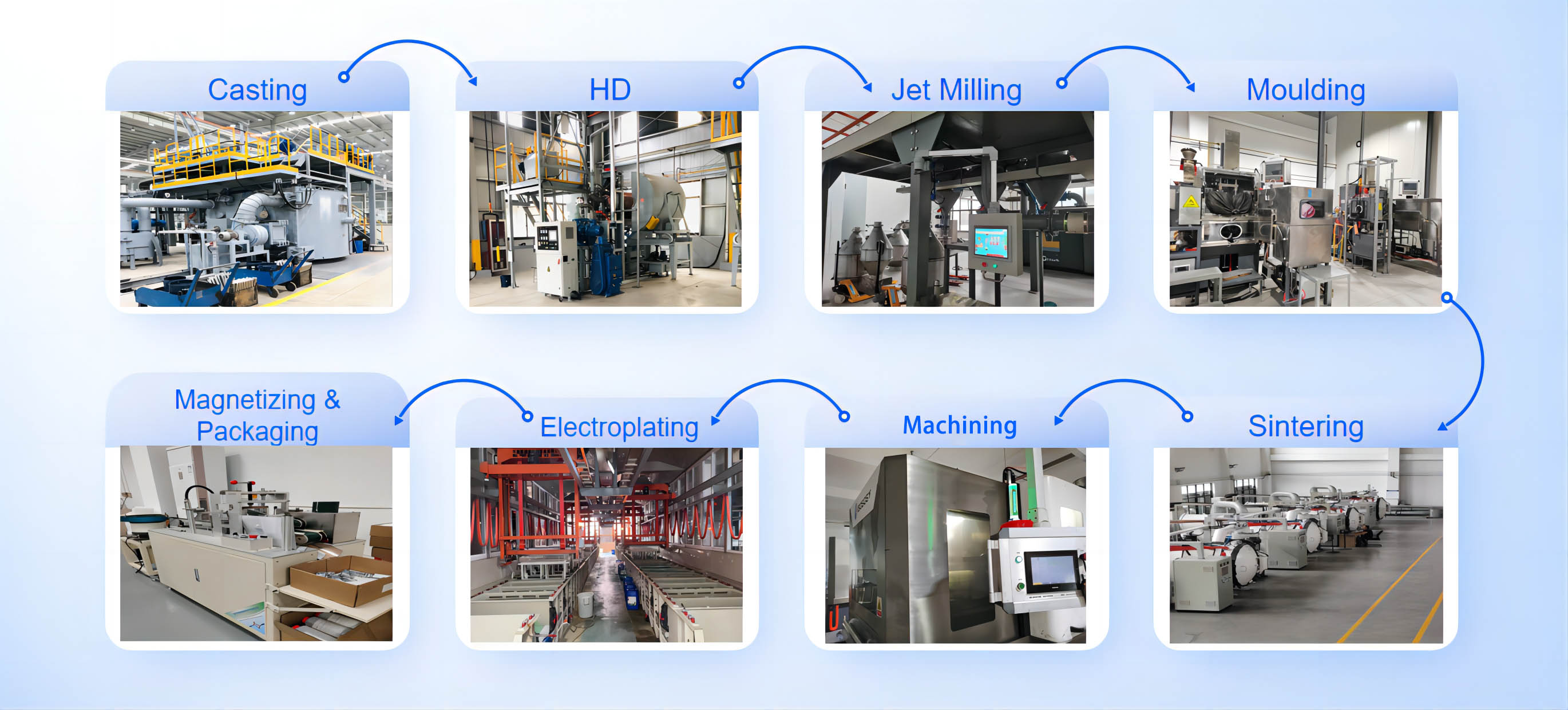

NdFeB Production Process

Coating Introduction

| Surface | Coating | Thickness μm | Color | SST Hours | PCT Hours | |

| Nickel | Ni | 10~20 | Bright Silver | >24~72 | >24~72 | |

| Ni+Cu+Ni | ||||||

| Black Nickel | Ni+Cu+Ni | 10~20 | Bright Black | >48~96 | >48 | |

| Cr3+Zinc | Zn C-Zn |

5~8 | Brighe Blue Shining Color |

>16~48 >36~72 |

--- | |

| Sn | Ni+Cu+Ni+Sn | 10~25 | Silver | >36~72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10~15 | Gold | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10~ 15 | Silver | >12 | >48 | |

| Epoxy |

Epoxy | 10~20 | Black/Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15~30 | >72~108 | --- | |||

| Zn+Epoxy | 15~25 | >72~108 | --- | |||

| Passivation | --- | 1~3 | Dark Grey | Temporary Protection | --- | |

| Phosphate | --- | 1~3 | Dark Grey | Temporary Protection) | --- | |

Physical Characteristics

| Item | Parameters | Reference Value | Unit |

| Auxiliary Magnetic Properties |

Reversible Temperature Coefficient Of Br | -0.08--0.12 | %/℃ |

| Reversible Temperature Coefficient Of Hcj | -0.42~-0.70 | %/℃ | |

| Specific Heat | 0.502 | KJ·(Kg ·℃)-1 | |

| Curie Temperature | 310~380 | ℃ | |

| Mechanical Physical Properties |

Density | 7.5~7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Electrical Resistance | 1.4x10-6 | μQ ·m | |

| Compressive Strength | 1050 | MPa | |

| Tensile Strength | 80 | Mpa | |

| Bending Strength | 290 | Mpa | |

| Thermal Conductivity | 6~8.95 | W/m ·K | |

| Young's Modulus | 160 | GPa | |

| Thermal Expansion(C⊥) | -1.5 | 10-6/℃-1 | |

| Thermal Expansion(CII) | 6.5 | 10-6/℃-1 |

Picture Display