Application: Widely used in brushless motor, permanent magnet industrial motor, textile motor, automobile motor, permanent magnet direct drive motor, linear motor, air conditioning compressor motor, mechanical equipment permanent magnet motor, Marine generator, permanent magnet generator, permanent magnet propulsion motor, mining permanent magnet motor, coupling motor, chemical permanent magnet motor,drive motor for EV, pump motor, EPS motor, sensor and other area.

Product customized: magnet are all customized,length can be from 0.5mm-200mm, width from 0.5mm-150mm, thickness from 0.5mm-70mm, which can meet most customers' requirement.

Coating: NdfeB magnet is easy to oxidize, so normally it need a coating, the coating that common used in the market like:

1. ZN plating ( a kind of metal coating,salt spray test can reach 24-48 hours, high cost performance, so it is one of the best choice for most customers).

2. NICUNI (a kind of metal coating, salt spray test can reach 48-72 hours, cost performance is higher than ZN, but still very widely used in the market the assembly condition is harsh, the product corrosion resistance requirements of the customer can choose).

3. Epoxy (non-metallic coating, non-magnetic conductivity, can reduce the motor eddy current loss, salt spray test can reach 72-96 hours, higher cost than ZN an NICUNI coating.)

4. Other coating that also used: Phosphate, Sn, Au, Ag, Parylene and so on...

Tolerance: Normally our magnet tolerance are +/-0.05mm after coating.

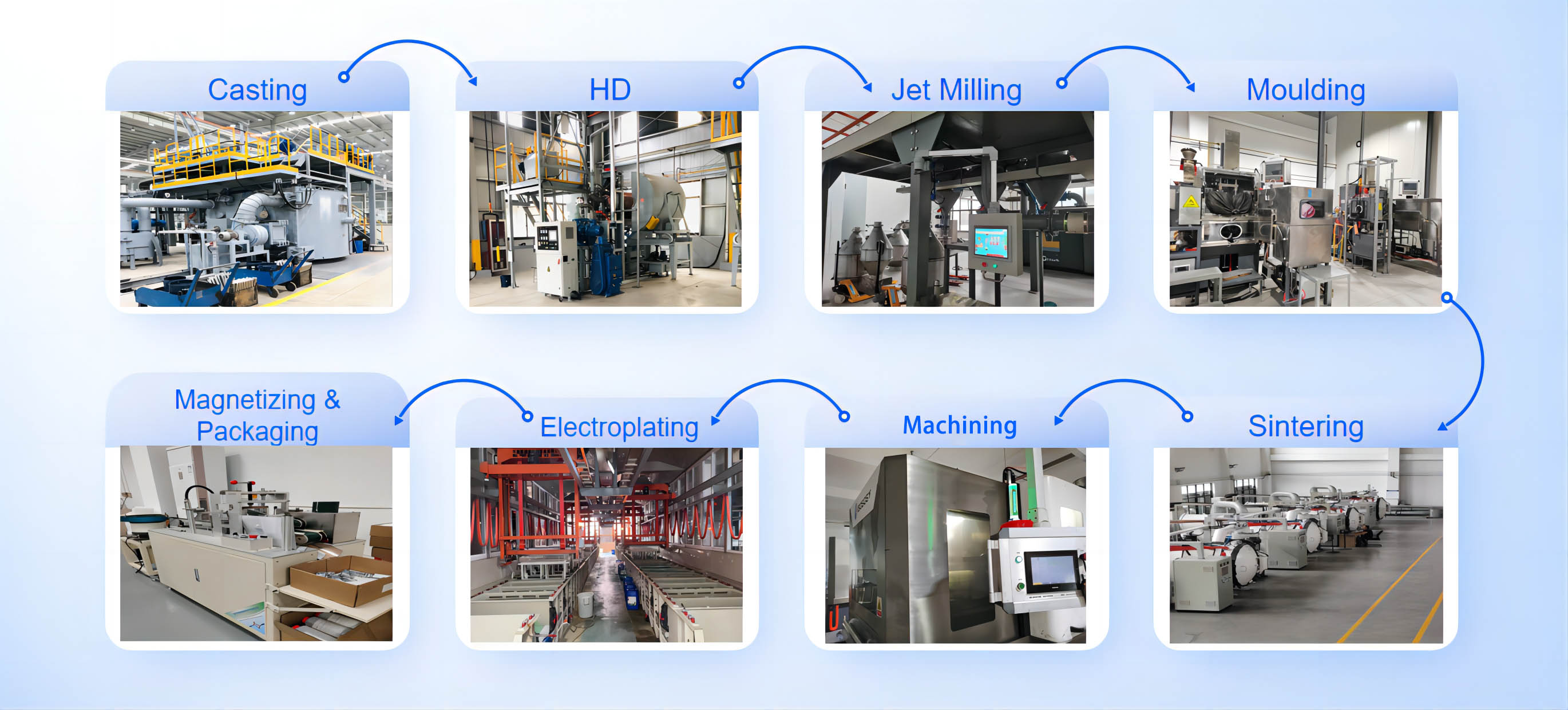

NdFeB Production Process

Coating Introduction

| Surface | Coating | Thickness μm | Color | SST Hours | PCT Hours | |

| Nickel | Ni | 10~20 | Bright Silver | >24~72 | >24~72 | |

| Ni+Cu+Ni | ||||||

| Black Nickel | Ni+Cu+Ni | 10~20 | Bright Black | >48~96 | >48 | |

| Cr3+Zinc | Zn C-Zn |

5~8 | Brighe Blue Shining Color |

>16~48 >36~72 |

--- | |

| Sn | Ni+Cu+Ni+Sn | 10~25 | Silver | >36~72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10~15 | Gold | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10~ 15 | Silver | >12 | >48 | |

| Epoxy |

Epoxy | 10~20 | Black/Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15~30 | >72~108 | --- | |||

| Zn+Epoxy | 15~25 | >72~108 | --- | |||

| Passivation | --- | 1~3 | Dark Grey | Temporary Protection | --- | |

| Phosphate | --- | 1~3 | Dark Grey | Temporary Protection) | --- | |

Physical Characteristics

| Item | Parameters | Reference Value | Unit |

| Auxiliary Magnetic Properties |

Reversible Temperature Coefficient Of Br | -0.08--0.12 | %/℃ |

| Reversible Temperature Coefficient Of Hcj | -0.42~-0.70 | %/℃ | |

| Specific Heat | 0.502 | KJ·(Kg ·℃)-1 | |

| Curie Temperature | 310~380 | ℃ | |

| Mechanical Physical Properties |

Density | 7.5~7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Electrical Resistance | 1.4x10-6 | μQ ·m | |

| Compressive Strength | 1050 | MPa | |

| Tensile Strength | 80 | Mpa | |

| Bending Strength | 290 | Mpa | |

| Thermal Conductivity | 6~8.95 | W/m ·K | |

| Young's Modulus | 160 | GPa | |

| Thermal Expansion(C⊥) | -1.5 | 10-6/℃-1 | |

| Thermal Expansion(CII) | 6.5 | 10-6/℃-1 |

Picture Display